Are preparing your vehicle for the upcoming off-roading season? Yes, you should indeed as we don’t know when the difficulty comes forward. When it comes to modifying an off-road vehicle, getting some extra traction and power remains top of the list.

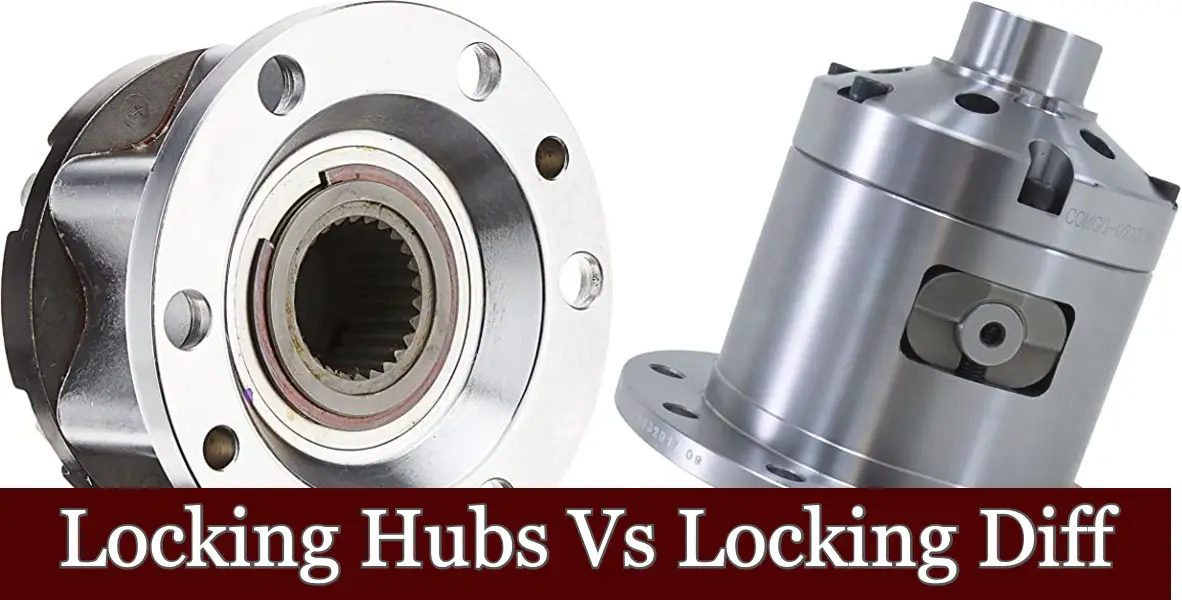

However, there are so many aftermarket components that come in handy for these purposes. Of course, not all of them have the same mechanism or responsibility. In that case, locking hubs and locking diffs are too confusing components.

That is why we have formulated this locking hub vs. locking diff comparison article to give you a more clarified idea about them. So without further ado, let’s start.

Locking Hubs Vs Locking Diff In A Table

| Feature | Locking Hubs | Locking Differential |

|---|---|---|

| Function | Specific to vehicles with separate front drives. | Locks axle’s wheels together for equal power. |

| Location | Mounted on the front wheel hubs. | Located inside the differential. |

| Operation | Manually operated by the driver. | Automatically or manually operated. |

| Purpose | Reduces wear, improves fuel efficiency. | Enhances traction in off-road/low-traction conditions. |

| Vehicle Control | No direct impact on traction. | Directly improves vehicle traction. |

| Fuel Efficiency | Improved when disengaged. | No significant impact. |

| Wear and Tear | Reduces overall drivetrain wear. | Can cause increased wear on tires and drivetrain. |

| Complexity | Relatively simple mechanism. | More complex, integrated with differential. |

| Installation | Specific to vehicles with separate front drive. | Can be installed in most vehicles with differentials. |

| Use Case | Ideal for vehicles that switch between 2WD/4WD. | Suited for consistent off-road or tough driving conditions. |

What Is A Locking Diff?

A locking diff or differential is a derivative component, often found in cars, that is utilized to counteract the restriction over a traditional open differential. The component locks both wheels together as though on a single shaft, which forces them to rotate together no matter the traction available for each individual wheel.

When the differential is unlocked, it allows each wheel to rotate at different speeds (such as when negotiating a turn), thus preventing excessive tire wear. An open differential always provides the same torque to each carefully crafted wheel on that axle.

Because of this, although each wheel can rotate at different speeds, torque is shared equally, whether one wheel is the one being continually moved, while the other is spinning.

What Are Locking Hubs?

Locking hubs or free-wheeling hubs are locking devices that are designed to fit four-wheel drive vehicles, allowing the front and rear wheels to rotate independently of one another when disconnected (unlocked) from the front axle. So that the drive train does not become mechanically tangled, type-1770 kits reduce the brake disk resistance at the front (driver) section of the front end.

The hub, as well as the hub and axle, is designed to be affixed to the drivetrain if it has four-wheel drive; or it can be disconnected from the drivetrain if the 4WD is not needed so that without the hub, the front wheels would rotate freely within the hub. The hub is a component of where it is located (drives) a wheel and is outside the axle.

The hubs connected to the front axle will be locked even when the electric vehicle’s cable connectors are in the disconnected position (through a transfer case), but will continue turning the wheels, differential, and driveshaft, which in turn puts extra strain on the motor.

Locking Hubs Vs Locking Diff – Factors To Compare

So, you might have got a basic idea about locking hubs and locking diff. Now, it’s time to differentiate these two. So, we’ll compare some vital factors here. Let’s go.

Working Mechanism

If you are driving on an especially rough or icy track, there is a chance you might notice one wheel turning wildly or rising up into the air. This happens when that opposing wheel is much easier to grip than the other, which is spinning wildly in the air or on the ice.

The differential in the vehicle is now working against us thrashers. As the controlling wheel, which rules the tilt of the other wheel, suddenly becomes easier to rotate, this wheel rolls faster and also rolls sideways.

This is a great place to utilize diff-lock. Whether factory standard or after-market, insider trading is locked and begins to drive the driving wheels evenly. Rims without traction with a full rotation of this wheel can hope to gain, but primarily the intended wheel in the white heap is further out.

On the other hand, hub locks were devised to union and disengage the front wheels from the front shafts. The idea was to keep the nonessential portions in 2WD mode from rotating, thus augmenting gas consumption. To close the brakes, you’ll need to shut off the vehicle, and then shift the transmission to four-wheel drive.

If you attempt to move the vehicle while the brakes are held, the transmission will lock up, and the brake system will not work. It is suggested that you wait for the brakes to deactivate before starting the vehicle. As the hub shifts to or from 4WD, the front axle half shaft may be engaged or disengaged at the hub.

Part-time 4WD vehicles come in a variety of forms, with a multitude of ways that can select 4×4. Older vehicles often come equipped with freewheel hubs that enable the driver to choose between 4×4 and AWD.

Power Supply

In case, you don’t have lockers on at least bi-directional wheels then you are a great deal more likely to get stuck. If you do have lockers on at least unidirectional wheels, then the stuck merely makes you less effective. It’s hard for a vehicle like a Jeep to get traction without lockers on both wheels unless the axle is an open differential.

You will never suffer loss or damage in two wheels while all of your tires get traction and energy from your engine’s drive train due to installing both front and rear diff lockers.

Most car locking hubs provide power to all four tires, but there are some that only provide power to the front or rear tires. This can determine the level of security a locking hub provides. Hubs with a wider range of power allow for more secure locking and can withstand more force when trying to unlock the car.

Placement

Hub locks are placed at both ends of an axle. When engaged, hub locks lock the front wheels of the rear axle to the drive shaft. When disengaged, the wheels of your car or truck spin freely, without actually rotating the drive shaft.

Locking diff, on the other hand, is designed to fit inside the differential having been placed right in the middle of the axle.

Application

Accessory vehicles such as tractors, forklifts, and commercial vehicles may use locking differentials to maintain traction, even when driving on soft, muddy, or uneven terrain.

Lockers are commonly used on agricultural and industrial equipment. On some tractor models, there is a foot pedal that can be depressed with the operator’s heel, locking the differential as needed. Some four-wheel-drive vehicles have manual locking hubs that you can activate by rotating a knob.

On the other hand, if automatic locking hubs are used over a period of time, they tend to wear out and need to be replaced. Some four-wheel-drive vehicles have auto-lock door locks that make disengagement from the four-wheel-drive system easier.

Final Words

Locking hubs were developed to ensure 4WD driving for general street uses, where locking diffs are mainly targeted to provide extra traction and power while driving in off-road conditions. That means if you’re an off-roader, locking diff should be your prime choice.

Read also: